Delays, wasted resources, and missed sales are often the result of poor planning and outdated systems. For manufacturers and distributors, relying on manual processes or legacy ERP tools makes it difficult to keep up with real-time demand, manage inventory effectively, or adapt quickly to disruptions.

Microsoft Dynamics 365 Supply Chain Management goes beyond traditional ERP features. Its built-in Material Requirements Planning (MRP) engine enables businesses to anticipate demand, align resources, and respond in real-time—all from a single platform.

In this article, we’ll take a closer look at how Dynamics 365’s MRP addresses common supply chain pain points and helps businesses reduce inventory holding costs, avoid production delays, and accelerate purchase cycle times—all while improving visibility into every stage of the supply chain.

Supply Chain Challenges Businesses Face

Supply chains today are more complex than ever before. What used to be a linear process now spans multiple continents, involving suppliers, manufacturers, and logistics providers. The global nature of modern supply chains means that companies must navigate different regulations, cultural differences, and time zones, which adds another layer of complexity to managing operations smoothly.

This increased complexity brings many challenges that can impact a business’s operational efficiency, profitability, and weaken customer satisfaction when not handled effectively.

1. Demand Volatility

One of the most difficult challenges supply chain leaders face is unpredictable demand. Rapid changes in buying behavior, shifting market trends, and global economic shifts make it difficult to plan accurately. Businesses that cannot estimate demand accurately risk either overstocking or understocking inventory. In fast-moving markets, demand volatility can disrupt production, delay deliveries, and put added strain on supplier relationships.

2. Unexpected Disruptions in Supply Chain

Natural disasters, geopolitical instability, or global pandemics can delay production and delivery. Even small interruptions in the supply chain can create major delays in production and fulfillment.

These disruptions can slow down entire supply chains, causing delays that affect everything from raw material availability to the delivery of finished goods.

3. Increasing Cost and Efficiency Pressures

As supply chains become more global and interconnected, competition has increased across nearly every industry. Businesses now face growing pressure to reduce operational costs while maintaining high standards for product quality and service delivery – often with shorter lead times and tighter margins. However, inefficiencies in critical areas such as inventory control, production planning, procurement, and distribution can quickly diminish profitability. A lack of coordination between suppliers, manufacturers, and logistics partners often results in extended lead times, missed delivery windows, and higher transportation costs, which could directly impact customer satisfaction and the bottom line.

4. Lack of Real-Time Visibility

Another significant challenge is the lack of real-time visibility and data transparency across the supply chain. Many companies still operate on spreadsheets, disconnected systems, or outdated software, and are forced to make decisions based on outdated information or gut instinct.

Without real-time insight into inventory, supplier performance, or production status, teams are left reacting to problems instead of preventing them.

This lack of visibility makes it difficult to identify bottlenecks, track shipments, optimize production schedules, and respond to demand fluctuations promptly.

Facing These Challenges in Your Own Operations?

How Does Dynamics 365 MRP Solve Supply Chain Challenges?

Built-In MRP for Smarter Supply Chain Planning and Processes

Traditional planning tools are no longer enough. Companies need integrated, data-driven solutions that provide real-time visibility, improve decision-making, and help them respond quickly to disruptions and shifting demand.

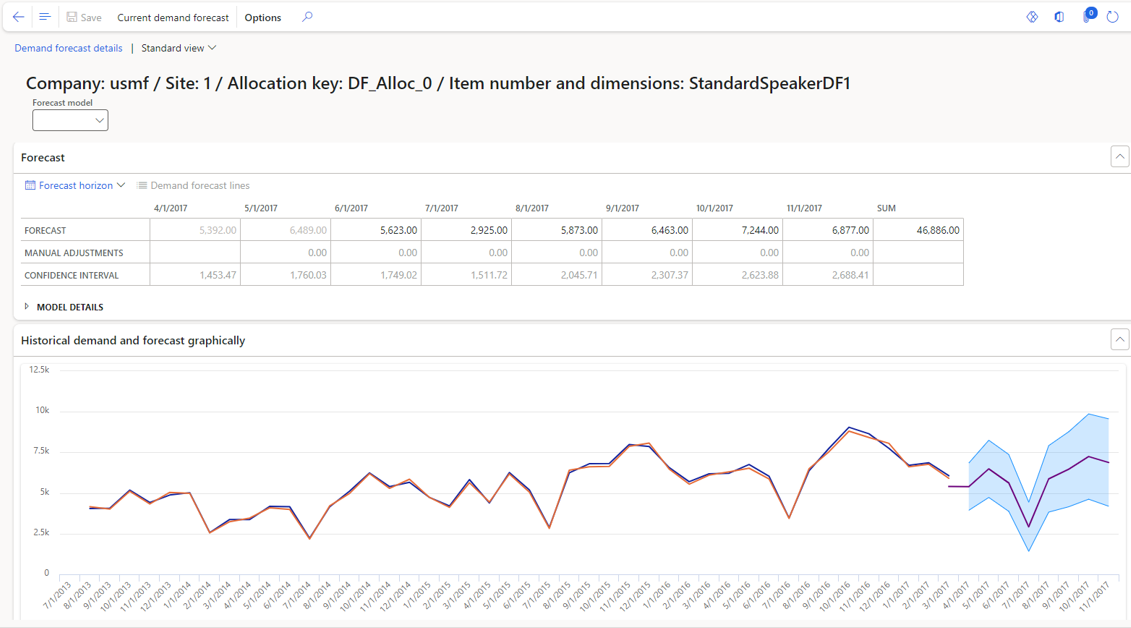

Screenshot within Dynamics 365 F&SCM – Historical Demand Forecast

Manufacturers are increasingly adopting advanced solutions like Microsoft Dynamics 365, which delivers real-time, AI-powered capabilities that help companies stay ahead of disruption. Its MRP functionality is built directly into the Supply Chain Management module, allowing businesses to forecast demand more accurately, optimize production schedules, and align procurement with real-time inventory data.

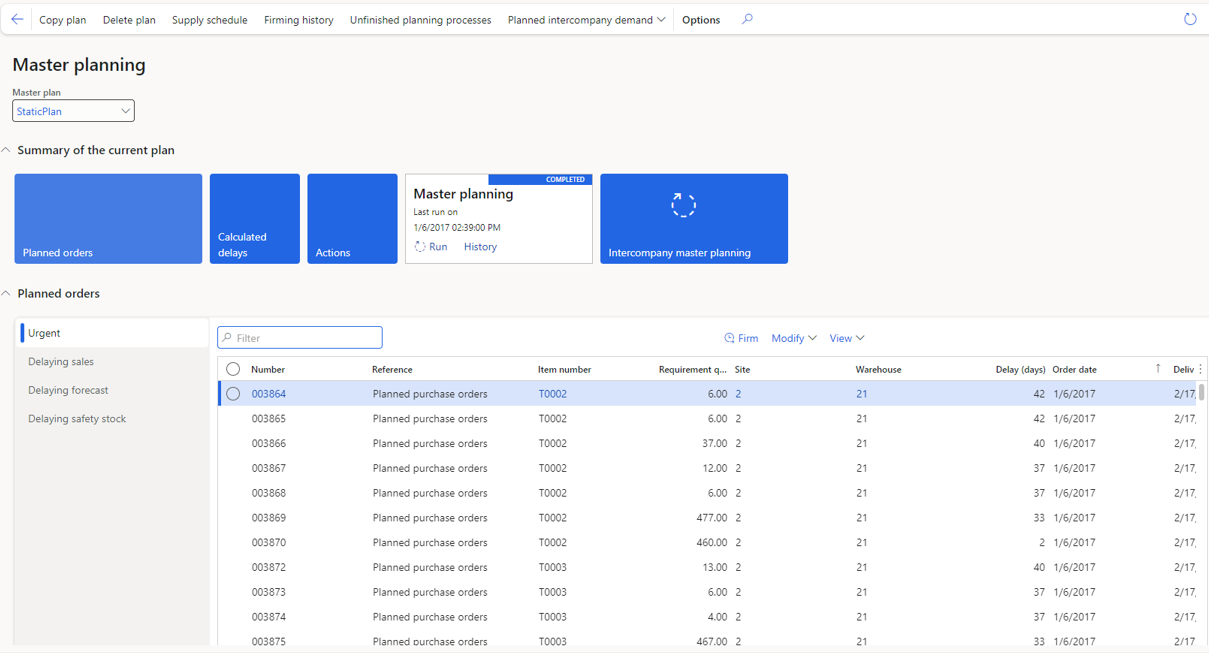

Screenshot within Dynamics 365 F&SCM – Master Planning

More Than Forecasting – Built for Efficiency

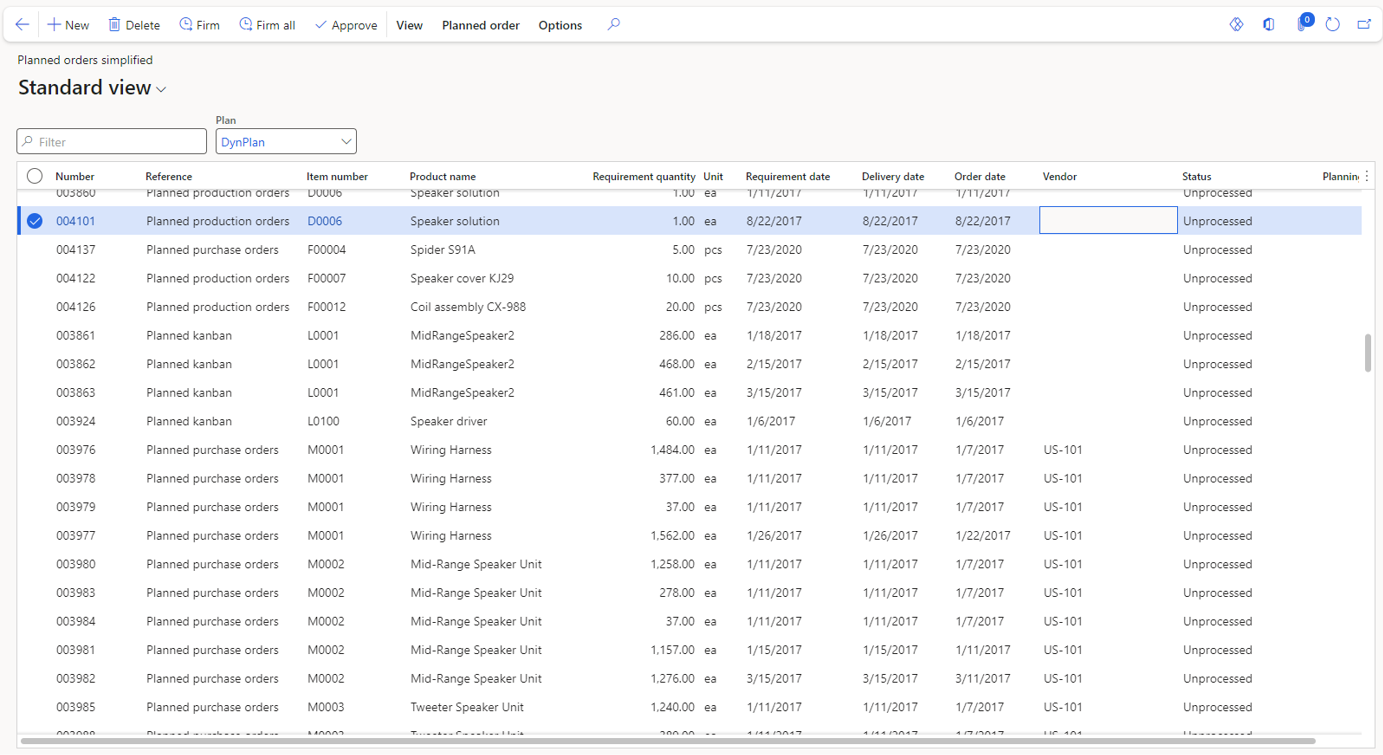

But the benefits go beyond just forecasting and visibility. It streamlines the entire planning and fulfillment cycle through intelligent automation. Key processes such as order management, inventory replenishment, and production planning are automated to reduce lead times and manual workloads.

By shifting from manual coordination to automated workflows, teams can shift their focus from day-to-day execution to more strategic activities and ultimately improve collaboration across the supply chain.

Key Features of Dynamics 365 MRP

Avoid Stockouts and Reduce Excess Inventory with Demand Forecasting & Inventory Control

- MRP uses historical sales patterns and AI-driven forecasts to predict material needs.

- Helps businesses adjust quickly to market shifts and align supply with demand.

- Reduces instances of overstocking or stockouts, optimizing inventory levels and capital usage.

Shorten Production Lead Times and Minimize Delays with Automation

- Automates material requirements planning and integrates real-time data across departments.

- Creates more efficient production schedules, minimizing bottlenecks and disruptions.

- Ensures smooth production runs, reducing delays that can affect customer deliveries.

Gain Real-Time Visibility Across the Supply Chain

- Provides full visibility into procurement, inventory, production, and distribution processes in real-time.

- Advanced reporting tools enable monitoring of KPIs and identification of areas for improvement.

- Teams can access live dashboards and reports that track performance metrics, identify delays, and flag risks early.

Lower Operating Costs Through Smarter Resource Allocation

- Aligns production schedules with actual demand, ensuring efficient use of resources (labor, materials, and equipment).

- Reduces the risk of overproduction and resource waste, reduces downtime and lowers operational costs.

- Enables data-driven decisions on purchasing materials, resource allocation, and cost-saving measures without compromising quality.

Scalable Solutions for Businesses of All Sizes

- Cloud-based infrastructure allows flexibility to scale operations up or down based on business growth and changing needs.

- SMEs can start small and expand as needed, while large corporations can manage complex, global supply chains efficiently.

Want to see how Dynamics 365 works in action?

Case Study: Automotive Manufacturer Transforms Supply Chain with Dynamics 365

A leading automotive components manufacturer specializing in process manufacturing was operating on a legacy ERP system that couldn’t keep pace with its evolving business needs. As production volumes grew, the limitations of their disconnected systems became more apparent. Delays in procurement cycles, difficulty tracking raw materials, and manual reporting created daily operational inefficiencies that slowed growth and affected customer commitments.

To modernize operations and gain control over its supply chain, the manufacturer partnered with Calsoft Systems to implement Microsoft Dynamics 365 Finance and Supply Chain Management to take advantage of its MRP capabilities.

Challenges before Dynamics 365 SCM implementation:

- Outdated ERP platform with limited scalability

- Manual processes for production planning and inventory tracking

- Disconnected procurement and finance workflows

- No real-time visibility into materials or capacity

- Inconsistent compliance reporting and traceability

- Operational growth was stagnating due to system limitations

- Urgent need for a unified solution connecting management, finance, supply chain, and manufacturing operations

Improvements After Implementing Dynamics 365 SCM:

- Improved production planning through centralized BOM (Bill of Materials) and real-time data

- Integrated procurement and finance functions, accelerating purchase cycles and improving cost oversight

- Improved visibility into inventory levels and supplier performance real-time dashboards

- Automated batch tracking for streamlined quality control and reporting

- Transitioned from legacy systems to a modern, cloud-based environment, enabling secure “anywhere, anytime” access

- Improved inventory management accuracy and reconciliation across integrated modules

- Reduced capital costs by eliminating the need for on-premise infrastructure with a scalable, cloud-first deployment

“We knew our existing business system couldn’t keep up with the needs of our expanding operations. After evaluating several options, we chose Microsoft Dynamics 365 Finance and Supply Chain Management because it aligned best with our manufacturing and planning requirements. Calsoft’s deep experience with manufacturing implementations made them the right partner to guide us through this critical transformation.”

Alan Hope

IT Director of MOC Products Company, Inc.

The implementation helped the client transition from manual workflows to a fully connected and automated system. This transformation led to significantly improved supply chain visibility, shorter lead times, and greater operational efficiency, setting them up for future growth and better customer service.

Next Steps for Transitioning to Dynamics 365 Finance and Supply Chain Management

A successful ERP implementation starts with a clear plan and the right partner.

Here’s how to approach your implementation with confidence:

1. Evaluate Your Current Supply Chain Operations

Begin with an evaluation of existing supply chain operations, including planning, procurement, inventory management, and production scheduling. Identify how it can solve your existing problems like inefficiencies, manual processes, data silos, and areas where visibility is lacking.

2. Set Clear Goals and Requirements

What current supply chain challenges are you trying to solve? Is it inaccurate forecasting, high inventory holding costs, delayed production schedules, or limited visibility across your supply chain?

Clear objectives keep your implementation focused and aligned with your business needs.

3. Engage Key Stakeholders

Involve decision-makers and end users from departments like operations, finance, IT, and procurement. Their input helps to align goals, validate requirements, and ensure cross-functional support.

4. Select an implementation Partner

Work with a certified Microsoft Dynamics 365 implementation partner who understands the technical aspects of Dynamics 365 and has industry-specific experience in supply chain and manufacturing environments. The right ERP team will guide MRP configuration, data migration, and change management with minimal disruption.

5. Clean and Prepare Your Data

Before migrating to Dynamics 365, ensure that critical data from legacy systems (inventory records, supplier details, BOMs, and production schedules, etc.) is cleaned, validated and standardized. Clean data is essential for accurate MRP calculations and reliable forecasting.

6. Train Users

User training is critical to the success of any ERP or MRP implementation. Emphasize the benefits of the new system, provide hands-on experience, and address concerns early to ease adoption and encourage engagement.

7. Test and Optimize

Before going live, run thorough system tests to ensure the MRP system functions as intended across all key workflows. This includes validating MRP calculations, production schedules, procurement logic, inventory updates, and end-to-end supply chain scenarios. Adjust configurations based on feedback and refine planning parameters as needed.

8. Go Live and Monitor Performance

Launch the system and closely monitor early performance metrics such as inventory turnover, lead time reduction, schedule adherence to assess system effectiveness. Gather user feedback to fine-tune workflows, adjust planning parameters, and optimize system configurations.

Want help building your implementation roadmap

Let’s talk about how we can support your transition to Dynamics 365—whether you’re starting fresh or upgrading from legacy systems.

Dynamics 365 MRP: Frequently Asked Questions

Material Requirements Planning (MRP) is a system used in manufacturing to calculate the materials, components, and scheduling needed to meet production demand. It helps businesses ensure they have the right materials at the right time to avoid stockouts, reduce excess inventory, and improve production efficiency.

Microsoft Dynamics 365 Supply Chain Management includes built-in MRP tools that automate production planning, optimize inventory, and align procurement with real-time demand. This reduces delays, lowers costs, and provides full visibility across the supply chain.

The benefits of Dynamics 365 MRP include improved demand forecasting accuracy, real-time supply chain visibility, shorter production lead times, reduced operational costs and waste, and a scalable cloud-based infrastructure that supports businesses of all sizes.

MRP systems are widely used in manufacturing, automotive, distribution, retail, and process industries. Businesses with complex supply chains, fluctuating demand, or heavy reliance on accurate forecasting gain the most value from MRP tools like those in Microsoft Dynamics 365.

The transition involves assessing current supply chain processes, setting clear goals, cleaning and migrating data, training users, and partnering with a certified Microsoft Dynamics 365 implementation partner. With the right approach, businesses can move from outdated, manual systems to a modern cloud-based solution that scales with growth.

Conclusion

Supply chains are no longer predictable, and traditional planning tools can no longer keep up. As disruptions increase and customer expectations rise, businesses need more than visibility—they need speed, adaptability, and data they can act on in real time.

Microsoft Dynamics 365 Finance and Supply Chain Management with built-in MRP capabilities gives you the power to move from reactive to proactive. From smarter forecasting to automated scheduling and real-time inventory insights, it enables you to optimize operations, control costs, and deliver reliably—no matter what the market throws at you.

Companies that embrace this level of digital agility are already gaining a competitive edge. Those that wait risk falling behind.

With a structured implementation plan and the right implementation partner, transitioning to Microsoft Dynamics 365 can deliver substantial long-term value.

See how Microsoft Dynamics 365 MRP can help you cut costs, improve forecast accuracy, and reduce lead times.

More to Read:

Streamline Business Flows with Dynamics 365 Supply Chain Management

Supply Chain Disruption Causes and How to Respond to Them

How Technology Can Drive Success in Automotive Industry