Feeling the pressure to reduce waste and improve production efficiency, but struggling to coordinate it all with your ERP? You’re not alone. Many manufacturing operations hit a wall trying to bridge the gap between lean principles and traditional systems.

But what if your ERP could actually support lean manufacturing? That’s exactly what Microsoft Dynamics 365 does when combined with the proven Toyota Kanban method. Together, they help manufacturers streamline operations, reduce waste, and adopt just-in-time production strategies with confidence. This makes Dynamics 365 a strong ERP for Toyota Kanban workflows and lean manufacturing.

Learn how Dynamics 365 for lean manufacturing enables real-time workflow visibility, better inventory control, and more responsive supply chain planning.

What is the Toyota Kanban System in manufacturing?

The short answer: The Toyota Kanban system is a visual workflow method used in lean manufacturing to control production and inventory. It signals demand using cards or boards, helping teams produce exactly what is needed at the right time.

Originally developed as part of the Toyota Production System, Kanban is designed to support just-in-time (JIT) production. Each card or signal represents a task, inventory need, or process step allowing teams to manage workflow visually, avoid overproduction, and keep inventory levels lean.

In practical terms, Kanban in manufacturing works as a real-time feedback loop between production and demand. When an item is used, a Kanban signal triggers replenishment. This eliminates waste, reduces lead times, and enhances flexibility on the shop floor.

Most ERP systems aren’t built with Kanban or lean practices in mind. This leads to teams juggling manual boards, spreadsheets, and disconnected tools, while the ERP handles everything else. That fragmentation slows decision-making, wastes time, and makes it harder to scale.

Common ERP limitations in lean environments:

- No built-in visual tools like Kanban boards

- Poor real-time inventory data

- Heavy reliance on manual workarounds

How Does Dynamics 365 Function as an ERP for Toyota Kanban?

Microsoft Dynamics 365 makes it easier to bring lean manufacturing and ERP together. With built-in support for Kanban and just-in-time (JIT) production, it eliminates the need for separate tools or manual spreadsheets. Everything from demand signals to supply chain planning can be managed in one connected system.

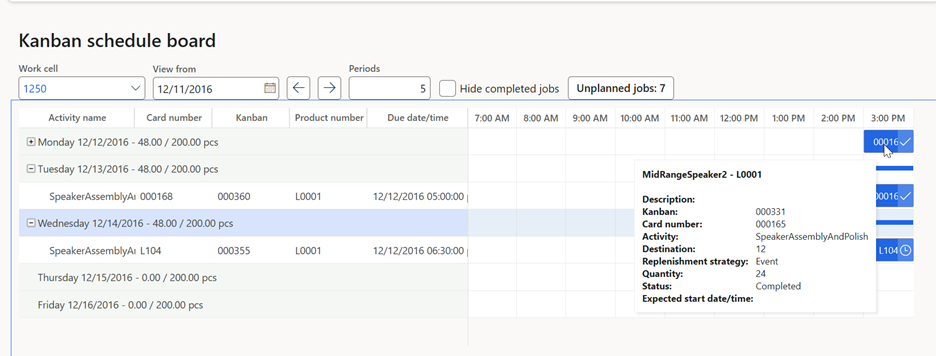

Visualize Workflows with Kanban Boards in Dynamics 365

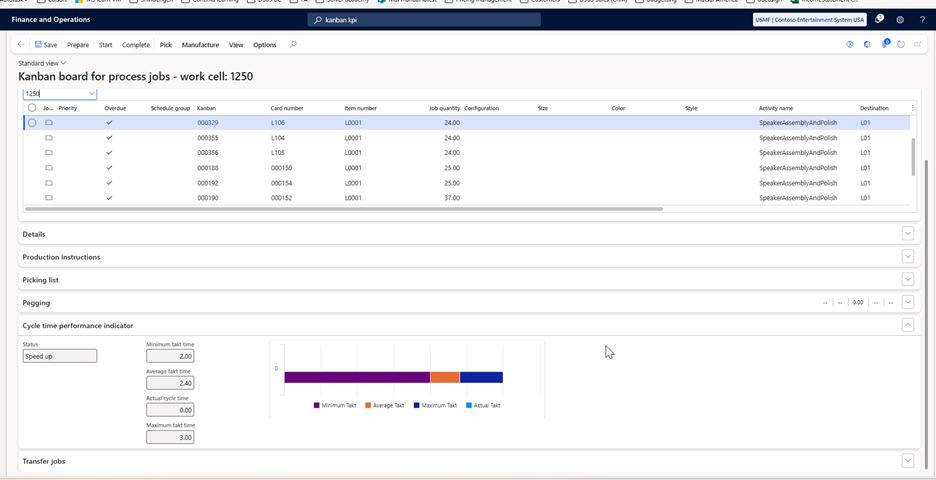

One of the biggest advantages of Dynamics 365 for Toyota Kanban is its Kanban board integration. It gives your team a clear, visual way to manage production from tracking real-time progress to adjusting schedules based on actual demand.

Each card represents a task or work item, helping teams to:

- Monitor work-in-progress at a glance

- Spot and resolve bottlenecks quickly

- Prioritize tasks based on real-time production needs

The Kanban boards in Dynamics 365 are modeled after the Toyota Kanban system, but with the accuracy and speed of a digital platform. You get full visibility into your production workflow without the clutter of sticky notes or whiteboards.

How to use a Kanban board in Dynamics 365:

- Create a production flow with cards for each task

- Assign cards to stages such as “In Progress,” “Ready,” or “Complete”

- Use real-time data to adjust production based on demand

Want to see what a digital Kanban board could look like for your team?

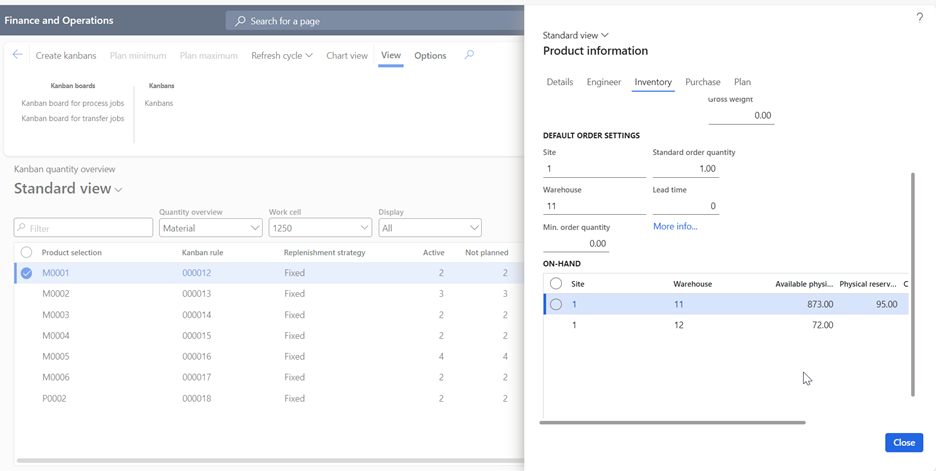

Real-Time Inventory Control with Just-in-Time Production

How does Dynamics 365 support just-in-time (JIT) manufacturing?

Dynamics 365 connects your production schedules with real-time inventory data, so you can trigger purchases and replenishments exactly when they’re needed.

When Kanban signals are connected to real-time inventory data in Dynamics 365, it becomes much easier to manage the flow of materials. Raw parts and components show up when they’re actually needed. That means less waste, fewer stockpiles, and a smoother production process overall.

With Dynamics 365 and JIT production, you get:

- Lower inventory carrying costs

- Fewer stockouts and production delays

- Smarter purchasing and replenishment cycles

Whether your goal is to cut excess inventory or streamline operations, just-in-time production becomes much easier to manage with an ERP for lean manufacturing like Dynamics 365.

Talk to us about streamlining your inventory with just-in-time workflows

Cut Waste and Improve Efficiency

How does Dynamics 365 help reduce waste in lean manufacturing?

At its core, lean manufacturing is about cutting out anything that doesn’t add value—whether it’s time, materials, or unnecessary effort. Dynamics 365 makes that easier by giving you visibility and tools to spot where things slow down or fall off track.

With built-in analytics and performance metrics, your team can:

- Pinpoint inefficiencies using built-in analytics

- Use AI to forecast and prevent disruptions

By acting on the data you already have, you can keep operations running smoothly and continuously find ways to improve.

Lean waste types addressed by Dynamics 365:

- Overproduction

- Excess inventory

- Waiting time

- Unnecessary movement or transportation across the shop floor

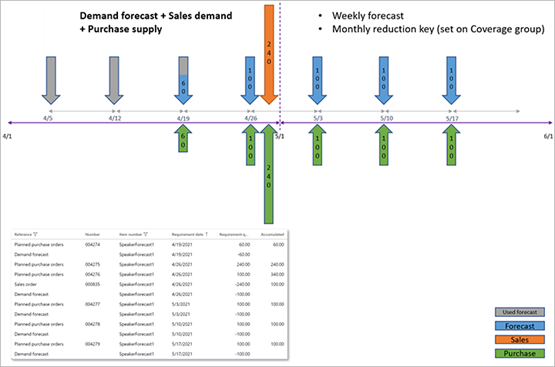

Collaborate Better Across the Supply Chain

How does Dynamics 365 improve lean supply chain management?

In lean manufacturing, your supply chain needs to be just as agile as your production line. Dynamics 365 makes that possible by improving how you connect and coordinate with suppliers, so everyone stays on the same page.

Here’s how it helps:

- Shares live demand signals with suppliers

- Makes collaboration easier through shared dashboards

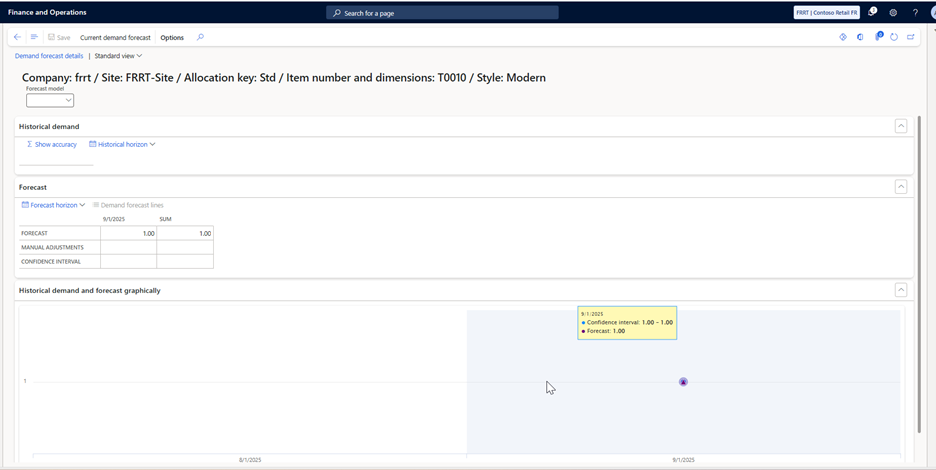

- Uses AI to forecast demand and avoid overstocking or running short

Because everything runs through one connected system, there’s no need to wait on email updates or guess what’s coming next. Vendors, planners, and production teams all have access to the same real-time data, helping you respond faster and make better decisions.

With stronger communication and more accurate forecasting, Dynamics 365 strengthens your supply chain from end to end, so weak links don’t slow you down.

Measure What Matters: Lean KPIs in Dynamics 365

Tracking performance is essential if you want to maintain and improve lean manufacturing practices. Dynamics 365 makes it easy by giving you a clear view of the metrics that matter most all in one place.

Key KPIs you can monitor in Dynamics 365 include:

- Cycle time: How long a product takes from start to finish

- Lead time: Total time between order and delivery

- First-pass yield: % of products made correctly the first time

- On-time delivery: % of orders delivered on schedule

With these insights built into your ERP, your team can stay focused on what’s working, spot issues early, and make fast, informed decisions that align with your lean manufacturing goals.

What KPIs should you track for lean manufacturing?

These four KPIs—cycle time, lead time, first-pass yield, and on-time delivery—offer a strong foundation for measuring efficiency, quality, and reliability. When tracked consistently, they help you keep operations lean, responsive, and competitive.

Want to implement the Toyota Kanban method with Dynamics 365?

Whether you’re starting your lean journey or upgrading your current system, Dynamics 365 gives you the tools to support Kanban manufacturing and just-in-time production—built into one powerful ERP platform.

Ready to eliminate waste, reduce costs, and simplify your production line?

Let’s talk about how Dynamics 365 for Toyota Kanban can help you modernize your workflows and get the most out of your ERP for lean manufacturing.

FAQ: Toyota Kanban and Dynamics 365

The Toyota Kanban method is a visual workflow system that uses cards or boards to signal demand and control production. It’s a core part of lean manufacturing and supports just-in-time (JIT) production by helping teams produce only what’s needed, when it’s needed.

Dynamics 365 Supply Chain Management includes Lean Manufacturing capabilities designed to align with the Toyota Kanban approach. Using digital Kanban boards, manufacturers can visualize work-in-progress, control production flow, and set up demand-driven replenishment policies. These tools help streamline operations, reduce waste, and improve responsiveness across the production process.

Yes. Dynamics 365 allows manufacturers to create digital Kanban boards, track WIP, and respond to real-time demand. Each card represents a task or item and moves through defined stages like “Ready,” “In Progress,” and “Completed.”

Reduced waste, better supplier coordination, real-time visibility, and automated inventory control.

With Dynamics 365, you can monitor critical lean KPIs such as cycle time, lead time, first-pass yield, and on-time delivery. These metrics help you measure efficiency, quality, and process reliability.

Absolutely. Dynamics 365 integrates production planning with real-time inventory data, enabling manufacturers to implement just-in-time processes that minimize excess inventory and reduce holding costs.

Still have questions? Let’s explore what Toyota Kanban could look like inside your production system.