Demand forecasting for automotive parts suppliers is one of the toughest challenges, especially for Tier 2 and Tier 3 businesses. Between shifting upstream demand and supply chain disruptions, both groups are under constant pressure. That’s why many are turning to ERP tools like Dynamics 365 supply chain forecasting to bring more control and accuracy to their operations.

In the automotive industry, suppliers are categorized into tiers that reflect their position within the production chain. Tier 1 suppliers work one-on-one with auto manufacturers (OEMs), supplying fully assembled systems such as braking systems or seats to auto manufacturers such as Toyota or Ford. Tier 2 supplies Tier 1 with subcomponents or specialty parts. At the base of the supply chain framework are Tier 3 suppliers whose responsibility is to provide basic raw materials and base parts. These range from companies that make metal stampings, plastic resins, rubber gaskets, or even fasteners. While they may not interact with OEMs directly, Tier 3 suppliers play a critical role in keeping the entire automotive supply chain running efficiently.

Why forecasting is a struggle for Tier 2 and Tier 3 automotive parts suppliers

For Tier 2 and Tier 3 automotive parts suppliers, building accurate forecasts is challenging because so many factors are outside their control. They operate with limited visibility into actual customer demand, often receiving incomplete or delayed information upper tiers. This makes it difficult to align raw material purchasing and production schedules with real market needs.

One of the biggest issues is supply chain fragility. Tier 2 suppliers can be disrupted when Tier 1 partners adjust orders unexpectedly, while Tier 3 suppliers are vulnerable to global price swings, commodity shortages, and shipping delays that restrict the flow of key materials such as steel, rubber, and plastics Even a brief delay in receiving these items can set off a chain reaction that affects every tier above.

This challenge is intensified by the pressure to meet just-in-time (JIT) delivery requirements from OEMs and upper-tier suppliers, often with little to no long-term visibility into demand Sudden schedule changes from OEMs or Tier 1 partners leave Tier 2 and Tier 3 suppliers scrambling to adapt, which leads to production inefficiencies, higher costs, and increased risk of stockouts or overproduction.

To make matters worse, many suppliers still rely on spreadsheets or disconnected legacy systems to manage forecasting. Without integrated planning tools and real-time collaboration, it’s nearly impossible to respond quickly and strategically. Implementing ERP solutions like Dynamics 365 supply chain forecasting helps Tier 2 and Tier 3 suppliers close this gap, improve forecasting accuracy, and move from reactive firefighting to proactive planning.

Why forecast accuracy matters

For Tier 2 and Tier 3 automotive suppliers, forecasting is about more than predicting demand. Forecasting is needed for revenue protection, relationship building, and operational stability. When forecasts go wrong, the cost is steep:

- Lost revenue from missed orders when production can’t keep up with sudden spikes in demand

- Wasted inventory that ties up capital when demand is overestimated

- Lower supplier scorecards from Tier 1 customers or OEMs, putting future contracts at risk

- Missed Service Level Agreements (SLAs) that damage credibility and may lead to financial penalties

Accurate forecasting changes this reality. With Dynamics 365 supply chain forecasting, Tier 2 suppliers can align production with multiple Tier 1 schedules, while Tier 3 suppliers gain clearer visibility into raw material requirements. Purchasing teams can order the right materials, production planners can schedule with confidence, and sales teams can anticipate upcoming demand shifts. The result is a more predictable supply chain, healthier margins, and deeper trust with partners across every level.

If your business is still relying on manual forecasting or disconnected systems, you’re leaving efficiency and profitability on the table. The right tools can help you close the gap.

Learn more about how Dynamics 365 Supply Chain Management improves forecasting accuracy

How Dynamics 365 enhances forecasting

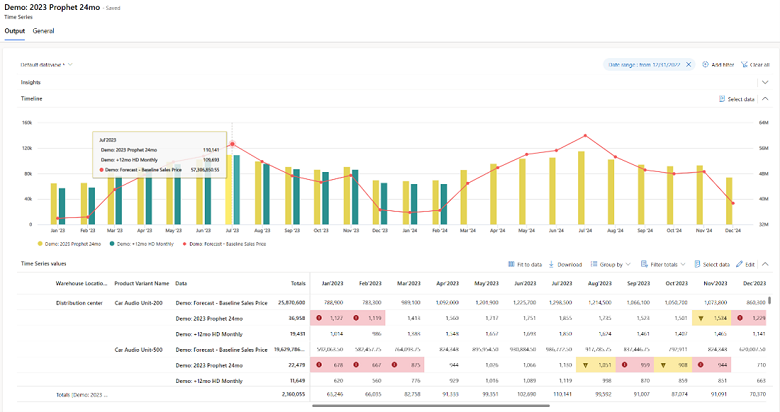

Microsoft Dynamics 365 transforms forecasting from guesswork into a strategic advantage. Its forecasting accuracy in Dynamics 365 tools gives Tier 2 and Tier 3 suppliers the ability to turn volatile demand patterns into actionable production plans.

- AI-Driven Demand Forecasting: Analyze historical sales data, seasonal patterns, and market trends to create forecasts that adapt as conditions change. This means fewer surprises, more accurate material planning, and reduced waste.

- Real-Time Visibility Across Operations: Access live data on orders, inventory, and production capacity from a single dashboard. With this visibility, decision-makers can spot potential shortages or bottlenecks early and take corrective action before they impact delivery schedules.

- Seamless Supply Chain & Production Integration: Forecast data flows directly into production planning, purchasing, and logistics modules. This keeps every department working from the same, up-to-date numbers, eliminating silos and costly miscommunication

- Instant Response to Upstream Changes: Receive and process EDI (Electronic Data Interchange) signals from Tier 1 in real time. This allows you to adjust production schedules immediately when upstream demand changes—avoiding last-minute scrambles and missed deadlines.

By combining predictive analytics, real-time data, and connected workflows, Dynamics 365 gives Tier 2 and Tier 3 suppliers the clarity to make informed decisions, the agility to adapt quickly, and the efficiency to maximize margins.

See how Calsoft helps suppliers implement Dynamics 365 for better forecasting and take control of your demand planning.

Getting started: 3 steps to improve forecast accuracy with Dynamics 365

Whether you’re a Tier 2 or Tier 3 supplier, adopting a modern forecasting solution doesn’t have to disrupt your operations. With the right approach, you can quickly begin seeing results:

1. Focus on the Most Impactful Modules

Start with Microsoft Dynamics 365 Supply Chain Management and Demand Forecasting to address the core areas that drive your planning accuracy.

2. Prepare Your Data and Team

Clean your historical order data, validate your current processes, and involve operations leads early so your team is ready to act on new insights.

3. Integrate with Existing Tools

Dynamics 365 connects with common MRP systems, supplier portals, and even Excel, so you can enhance your forecasting without overhauling your entire tech stack.

With the right setup, you can replace guesswork with reliable data, improve supplier relationships, and boost profitability through smarter, faster decision-making.

Talk to Calsoft about implementing Dynamics 365 for smarter demand forecasting and start building a more predictable, efficient supply chain.

Conclusion

Tier 2 and Tier 3 suppliers play a critical role in the automotive supply chain, but forecasting challenges often hold them back, from fluctuating Tier 1 demands to raw material shortages and volatile markets. Dynamics 365 supply chain forecasting gives these suppliers the visibility, agility, and accuracy they need to move from reactive decisions to proactive planning. By adopting the right tools, suppliers can reduce waste, protect margins, and strengthen relationships across the supply chain.

Frequently Asked Questions

Tier 2 and Tier 3 suppliers can improve forecast accuracy by adopting integrated planning tools like Microsoft Dynamics 365, which use AI-driven demand forecasting, real-time data visibility, and supply chain integration. With Dynamics 365 supply chain forecasting, Tier 2 and Tier 3 suppliers can replace spreadsheets with predictive analytics, respond faster to changes from Tier 1 partners, and consistently meet delivery commitments.

Forecasting is difficult because Tier 2 and Tier 3 suppliers often lack real-time demand visibility and must adapt to upstream changes without notice. Legacy systems only make this harder. A modern forecasting tool like Dynamics 365 provides the data and tools needed to reduce uncertainty and improve responsiveness.

Accurate forecasting improves on-time delivery, lowers costs, and strengthens Tier 1 relationships by helping suppliers plan smarter and operate more efficiently.

Many Tier 2 and Tier 3 automotive suppliers consider Microsoft Dynamics 365 one of the most effective forecasting solutions because it combines AI-driven demand forecasting, real-time supply chain visibility, and seamless integration with existing ERP and MRP systems. With tools like Dynamics 365 supply chain forecasting, suppliers can anticipate demand shifts, align production with customer requirements, and improve on-time delivery rates while reducing waste and inventory costs.