Supply chain disruptions are happening more often and costing businesses more than ever. From global events to supplier delays and unpredictable demand, businesses face a wide range of risks every day. And when you don’t have the right tools in place, even small issues can lead to bigger problems across your operations.

That’s why many organizations are turning to modern supply chain risk management solutions that enhance transparency and help identify threats early, allowing businesses to act before problems escalate. Modern supply chain risk management tools leverage AI and real-time data to support long-term resilience.

In this blog, we’ll explore how Microsoft Dynamics 365 supports effective risk management across the supply chain through real-time data, automation, and intelligent forecasting. Whether you’re working with local suppliers or managing a global network, Dynamics 365 provides the insights, automation, and flexibility needed to support a solid supply chain risk management plan.

Common Risks in Modern Supply Chains

Supply chains are expected to deliver faster, operate leaner, and stay competitive. At the same time, they must manage a growing number of risks that can disrupt operations at any point.

Without the right supply chain risk management solutions, it becomes difficult to respond quickly or plan ahead. Here are some of the most common risks companies face today:

- Supplier delays or financial failures causing production stops and delay fulfillment

- Geopolitical factors like tariffs, trade restrictions, or regional instability that disrupt supply routes

- Fluctuating demand patterns often result in overstock or unexpected shortages

- Cybersecurity threats and compliance risks exposing your data and damaging business reputation

- Lack of real-time inventory visibility, making it difficult to respond quickly to sudden changes

To better understand the root causes behind these disruptions and how businesses can respond strategically, read our post on supply chain disruption causes and response strategies.

These risks can impact every part of the supply chain. However, with the right supply chain risk management solutions in place, companies can improve visibility, strengthen collaboration, and respond more effectively when disruptions occur.

These challenges also highlight the need for more advanced supply chain risk solutions, especially as businesses expand into new regions. As operations become more distributed, businesses are placing greater emphasis on global supply chain risk management to navigate disruptions across regions, suppliers, and regulatory environments.

Conducting a thorough supply chain risk analysis allows businesses to uncover hidden vulnerabilities, prioritize risk areas, and build more targeted mitigation strategies. A well-defined supply chain risk management process helps mitigate both short-term disruptions and long-term vulnerabilities.

How Dynamics 365 SCM Solves These Challenges

To manage supply chain risks, businesses need more than spreadsheets or disconnected systems. They need a centralized solution that brings clarity, speed, and control to every part of the operation. This is where Microsoft Dynamics 365 Supply Chain Management stands out.

As a powerful supply chain risk management software, Dynamics 365 helps companies identify issues early and keep goods moving.

Let’s break down how Dynamics 365 addresses each supply chain risk:

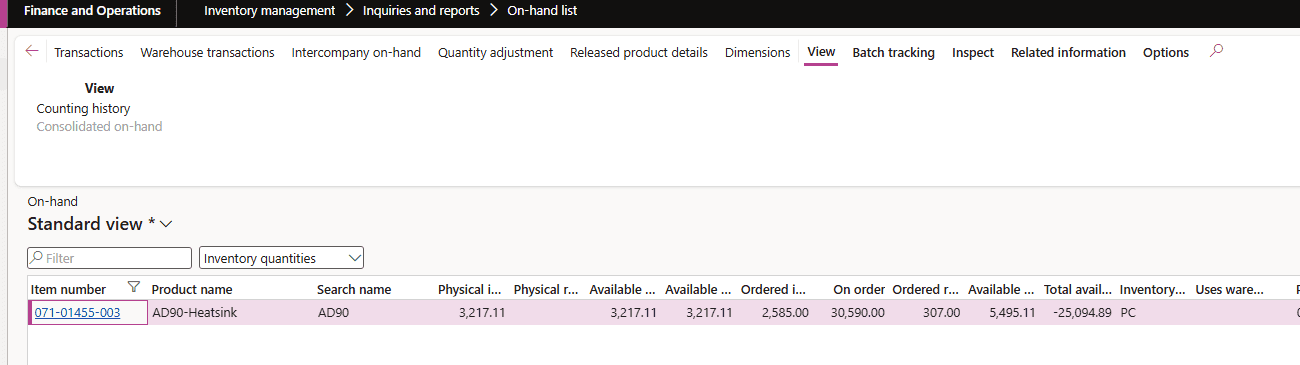

Real-time visibility gives you a clear view of inventory, production, and logistics across all locations.

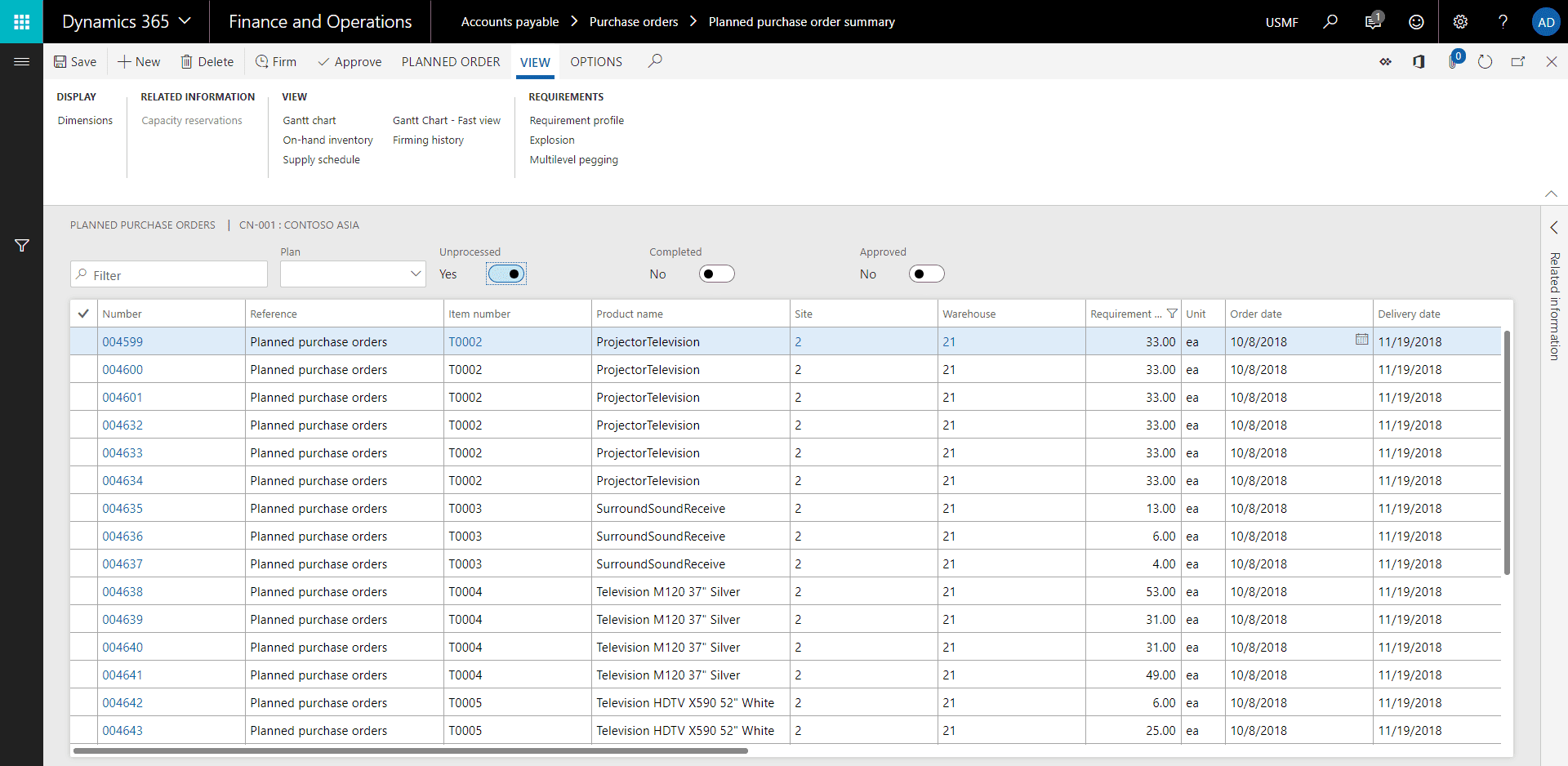

AI and machine learning tools improve forecasting accuracy, helping you respond to changes in demand with confidence.

Risk-based inventory planning helps you avoid shortages or overstock by aligning supply with risk profiles.

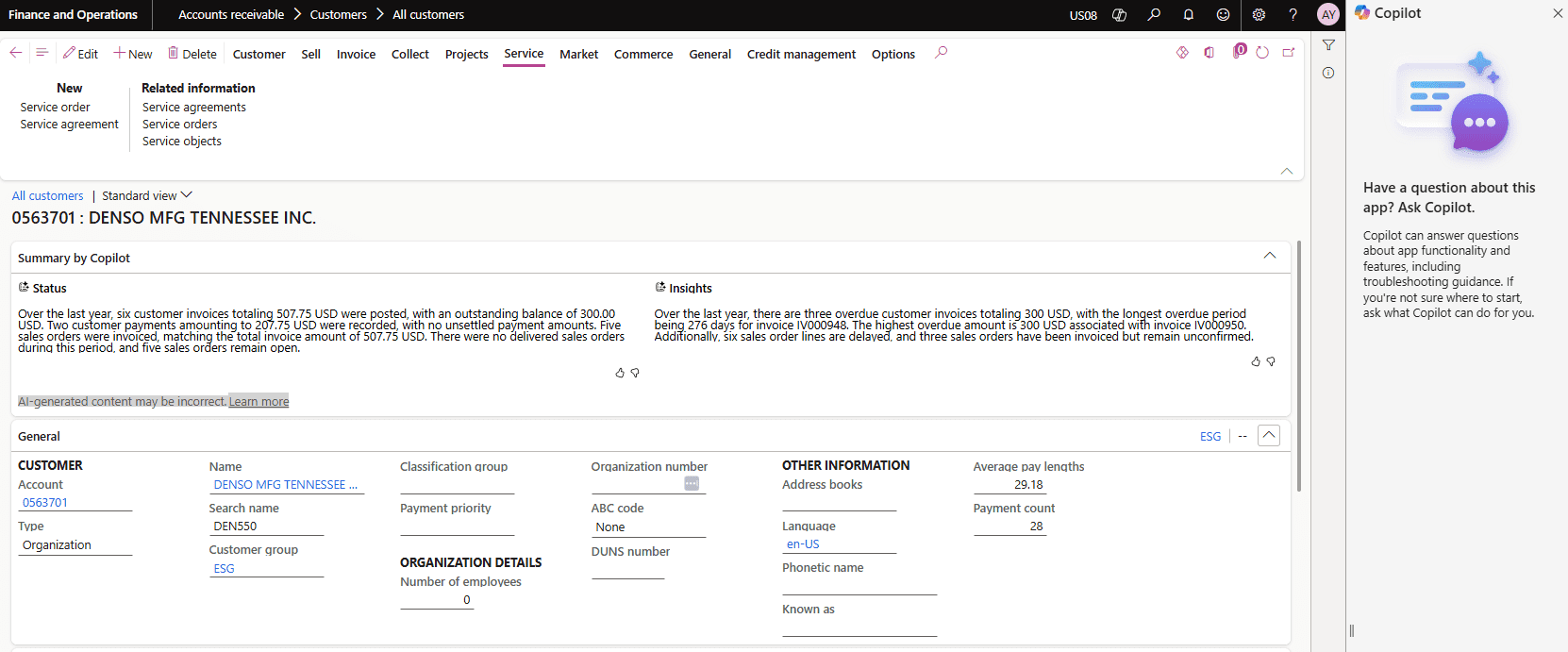

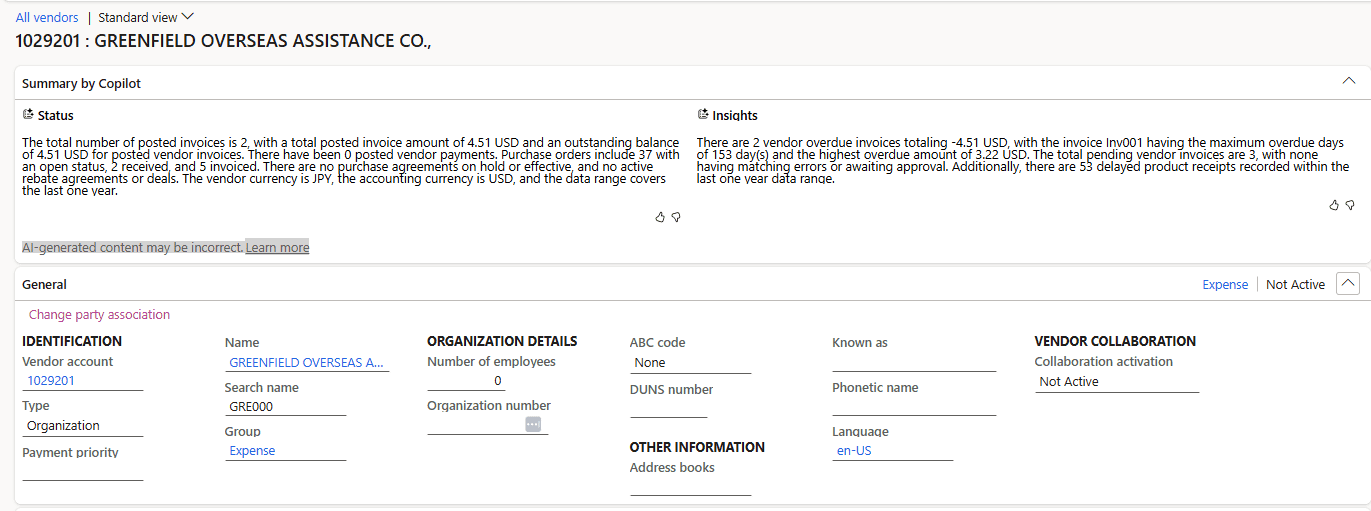

Supplier evaluation tools make it easier to track performance, manage compliance, and reduce dependency on unstable vendors.

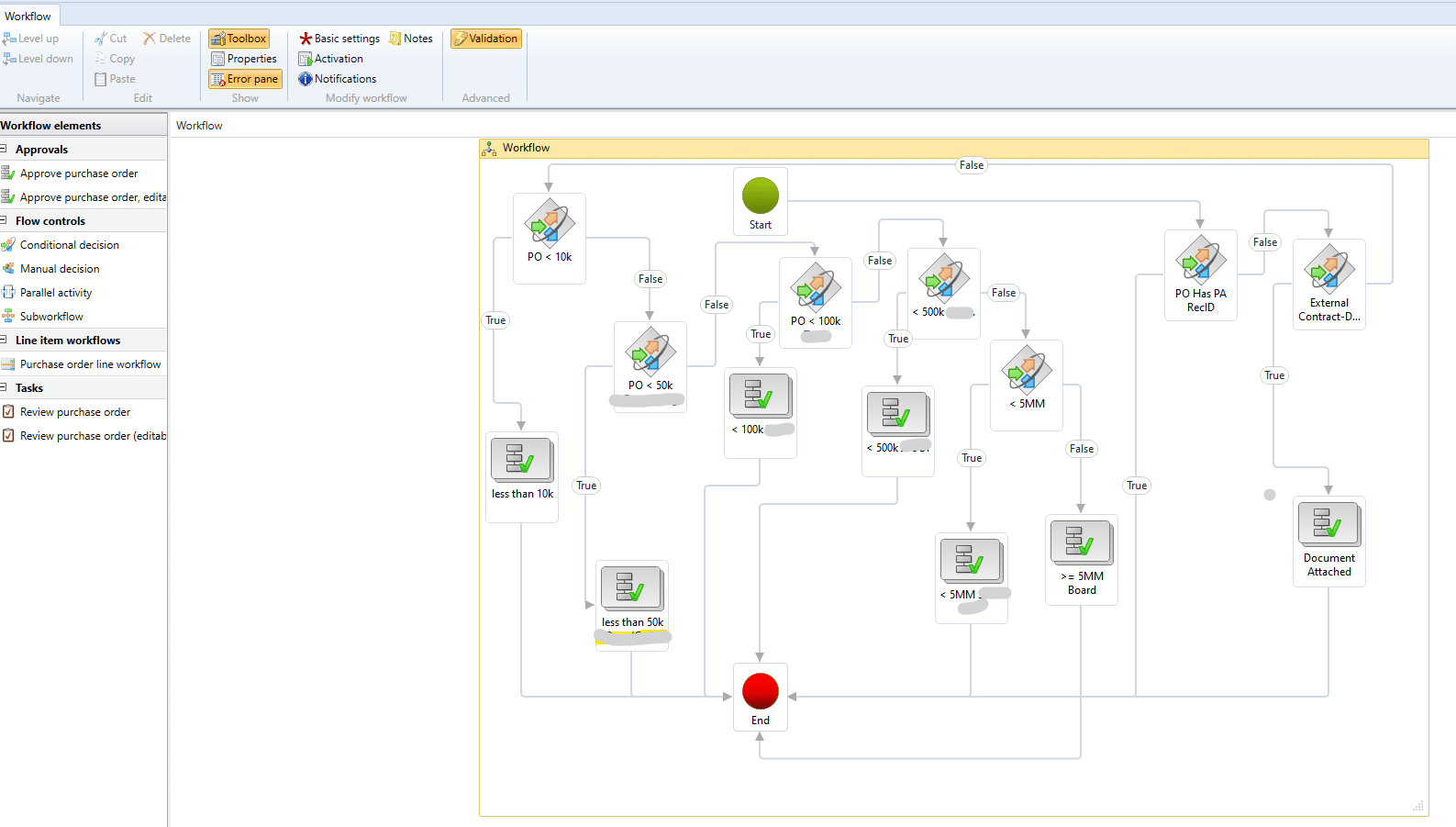

Automated workflows streamline corrective actions and ensure consistent handling of quality, safety, and compliance issues.

Dynamics 365 SCM combines operational data with intelligent features so your team can act fast and stay ahead. With the right supply chain risk management software, you can strengthen your supply chain and protect your business from unexpected disruption.

In addition to Supply Chain Management, other Dynamics 365 apps strengthen your risk strategy:

- Dynamics 365 Finance supports risk modeling, financial impact analysis, and budget forecasting

- Power BI offers real-time dashboards for better visibility and faster decisions

- Microsoft Sustainability Manager helps track ESG-related risks and reporting

Want to see how these features work in real time?

Business Impact of an Integrated ERP and Supply Chain Risk Management Approach

When your ERP system and risk management tools work together, your supply chain becomes more connected, more agile, and better prepared for change. An integrated supply chain risk management approach gives teams the insights they need to act fast and make smarter decisions across the board.

Here’s what that looks like in action:

- Faster response times when disruptions occur, reducing downtime and delays

- Lower financial losses by avoiding costly supply interruptions and stock issues

- Smarter procurement planning, with better visibility into supplier risk and performance

- Improved customer satisfaction through more reliable delivery and service levels

- Better alignment with ESG and regulatory goals, keeping your operations compliant and forward-thinking

Microsoft Dynamics 365 delivers all of these benefits through a unified, cloud-based platform. It combines real-time data, automation, and predictive tools to support every link in your supply chain. The result is a stronger, more resilient business that can adapt quickly—no matter what comes next. Learning how to mitigate risk in the supply chain is essential for building long-term resilience.

How MOC Products Strengthened Their Supply Chain with Dynamics 365

When MOC Products, a leading manufacturer of automotive service solutions, needed to modernize their operations, they turned to Microsoft Dynamics 365 to improve visibility, streamline processes, and reduce risk across their supply chain.

Before implementing Dynamics 365, MOC struggled with disconnected systems that limited visibility into inventory, production schedules, and supplier activity. This made it harder to respond to disruptions, forecast accurately, and maintain consistent delivery performance.

The implementation of Dynamics 365 Supply Chain Management gave MOC Products new capabilities, including:

- Real-time visibility across warehouses and production lines F

- Improved planning and procurement workflows, reducing delays

- Tighter supplier coordination, minimizing stockouts and last-minute adjustments

- Standardized processes that reduced manual errors and compliance risks

What if supply chain risk management could actually make your business stronger? That’s what MOC Products achieved with Dynamics 365. By moving to an integrated system, MOC was able to respond faster to changes and reduce operational uncertainty.

Ready to make your supply chain more resilient?

Let’s talk about how Microsoft Dynamics 365 can help you reduce risk and improve operations.

Supply Chain Risk Management: Frequently Asked Questions

Supply chain risk management is the process of identifying, assessing, and responding to potential disruptions that could impact the flow of goods, services, or information across your supply network. This includes everything from supplier delays and geopolitical issues to cyber threats and inventory imbalances.

Start with a clear supply chain risk management process that includes supplier evaluations, real-time visibility tools, predictive forecasting, and contingency planning. Platforms like Microsoft Dynamics 365 provide the technology to identify, prioritize, and respond to risk before it disrupts your operations.

Microsoft Dynamics 365 provides integrated tools for supply chain visibility, AI-based forecasting, supplier evaluation, and risk-based inventory planning. It serves as a centralized supply chain risk management software that allows businesses to respond quickly to disruptions and build long-term resilience.

A typical plan outlines how to identify potential risks, assess their impact, define mitigation strategies, assign response teams, and monitor outcomes. With tools like Dynamics 365, companies can also integrate these plans into their operational workflows.