Supply chains today face more pressure than ever before. Globalization has created longer and more complex supplier networks. Geopolitical tensions, trade restrictions, and sudden economic shifts increase uncertainty. On top of that, cyber threats and tighter compliance requirements have added new layers of risk that businesses must navigate every day. Even a minor disruption can now ripple across multiple regions, suppliers, and customer segments.

In this blog, we’ll explore how Microsoft Dynamics 365 Supply Chain Management delivers modern supply chain risk management solutions. These solutions help organizations address disruptions earlier and respond faster. You’ll learn about the built-in features and capabilities that support effective supply chain risk management. Whether you’re managing a global supply network or working with local partners, these tools can help you identify risks early, respond faster, and build long-term resilience.

If you’re looking for a broader overview of supply chain risk management challenges and how ERP systems support them, start with our guide on Supply Chain Risk Management Software for ERP Users.

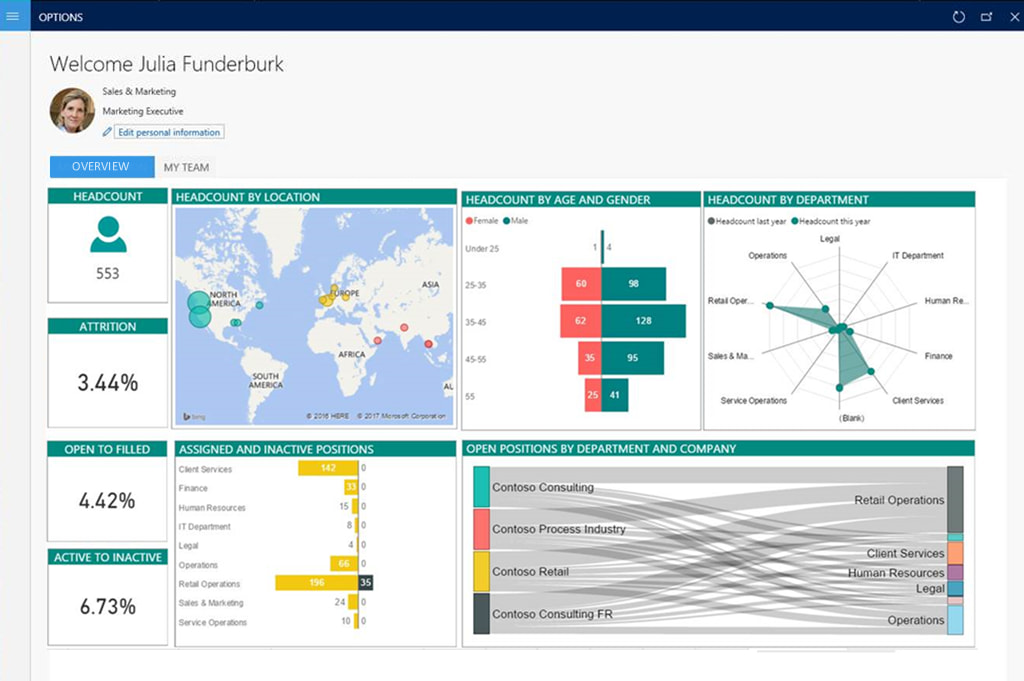

Supply Chain Visibility with Dynamics 365 and Power BI Dashboards

One of the biggest challenges in supply chain management is the lack of real-time visibility. Without timely insight into inventory, supplier performance, logistics, and demand, businesses are forced to operate reactively. This often results in stockouts, overstocking, delayed shipments, and costly inefficiencies.

Microsoft Dynamics 365 Supply Chain Management acts as a centralized control tower. It pulls live data from procurement, warehousing, production, and delivery into one view. Microsoft Dynamics 365 Supply Chain Management acts as a centralized control tower. It pulls live data from procurement, warehousing, production, and delivery into one view. Native supply chain risk management tools make it easier to track disruptions as they happen. Inventory Visibility, Supply Chain Insights, and Planning Optimization help decision-makers see issues early.

To take visibility even further, many organizations choose to extend Dynamics 365 with Microsoft Power BI, which integrates seamlessly with ERP data to create dynamic, real-time dashboards. These interactive reports allow teams to monitor key metrics at a glance. This includes stock levels, supplier performance, and on-time delivery rates. Teams can respond to risks earlier.

Together, Dynamics 365 and Power BI deliver a comprehensive supply chain risk management solution for supply chain transparency. Businesses gain not just visibility but the ability to act on insights immediately. For companies focused on building a resilient and proactive supply chain, this integrated approach turns data into a competitive advantage.

ERP Supply Chain Tools for Automated Inventory Management

Inventory management is a constant balancing act. Too much inventory ties up capital and storage space, while too little can lead to stockouts, missed sales, and delayed fulfillment. Finding the right balance is challenging, especially when relying on manual tracking or disconnected systems.

By leveraging built-in ERP supply chain tools such as Demand Forecasting and Planning Optimization, Dynamics 365 SCM makes inventory control more accurate and efficient. These features use historical sales data, market trends, and real-time inputs to generate more accurate forecasts and automatically adjust reorder quantities and inventory levels.

This level of automation positions Dynamics 365 SCM as a highly effective supply chain risk management solution. Organizations can maintain optimal stock levels while preventing costly disruptions. Dynamics 365 SCM aligns inventory with supply, demand, and financial objectives. This helps reduce excess inventory, lower carrying costs, and improve working capital efficiency.

Because Dynamics 365 SCM connects purchasing, warehousing, and finance within a single cloud-based platform, it ensures that inventory decisions align with supply availability, financial goals, and customer demand. This reduces excess stock, prevents costly stockouts, and enables smarter, data-driven inventory control across the entire supply chain.

Predictive Analytics in Supply Chain Logistics with Dynamics 365

Logistics can make or break a supply chain. Delays, bottlenecks, and inefficient routing quickly increase costs and impact customer satisfaction. In logistics, even small route inefficiencies can multiply into higher costs and delayed orders. These are challenges that traditional planning methods struggle to address.

Microsoft Dynamics 365 Supply Chain Management includes built-in AI capabilities (Copilot) and predictive analytics. These capabilities help businesses move from reactive to proactive logistics planning. Features such as Transportation Management, Route Optimization, and Planning Optimization continuously analyze shipment data, carrier performance, and delivery patterns to forecast potential risks before they occur.

By leveraging predictive analytics for supply chain logistics, organizations can anticipate delays, reroute efficiently, and minimize the financial and operational impact of disruptions. The system also evaluates multiple “what-if” scenarios, allowing planners to simulate alternate routes, capacity constraints, and delivery timelines.

When enhanced with Microsoft Copilot, Dynamics 365 SCM goes a step further by recommending actions and generating summaries. This AI-powered approach ensures shipments remain on schedule, costs stay under control, and supply chains remain resilient even when conditions change.

This combination of AI and predictive intelligence transforms logistics from a reactive function into a proactive strategy. Dynamics 365 Supply Chain Management stands out among the most advanced supply chain risk management solutions.

Protect Supply Chain Data with a Secure Cloud ERP

As supply chains become increasingly digital, they also face greater exposure to cyber threats. And it’s not just large enterprises at risk. According to IBM, over 60 percent of supply chain attacks target small and mid-sized businesses, many of which lack the tools to respond and recover effectively.

Built on Microsoft Azure, Dynamics 365 secures supply chain operations with enterprise-grade protection. The platform helps safeguard sensitive supply chain data through a Zero Trust security model and continuous monitoring. This means every user and device must be authenticated and authorized before accessing your data. Azure also provides robust features such as encryption, automated threat detection, and real-time monitoring to keep sensitive information secure without slowing down your business.

For growing companies, this level of protection offers more than just peace of mind. Even smaller businesses can benefit from the same cybersecurity infrastructure trusted by global enterprises. If you’re considering supply chain management software, a secure, cloud-based ERP like Dynamics 365 not only safeguards your data but also prepares your organization for scalable, long-term growth.

AI in Supply Chain Risk Management and Supplier Collaboration

One of the most valuable components of modern supply chain risk management solutions is the use of AI. It helps improve supplier collaboration and detect disruptions before they escalate. When communication with suppliers breaks down, the consequences can be serious. Production slows, costs rise, and customers are left disappointed. The bigger challenge is ensuring suppliers remain reliable and transparent. Without clear performance data, teams rely on guesswork. This weakens collaboration and increases costs.

Microsoft Dynamics 365 SCM, combined with Supply Chain Insights and Copilot, uses AI to monitor supplier performance, detect early warning signs, and flag potential risks before they escalate.

Supply Chain Insights (Microsoft Azure + Dynamics 365 Integration)

This is the most AI-driven component for supplier risk detection. It enables your team to:

- Monitor real-time supplier performance data

- Detect anomalies such as delayed shipments or quality inconsistencies

- Forecast potential supply disruptions before they impact operations

- Receive alerts that help prioritize and respond to supplier risks

Microsoft Copilot in Supply Chain Management

Copilot is being gradually integrated into Dynamics 365 SCM. Current capabilities include:

- Proactive risk notifications based on supply chain data

- Context-aware suggestions to support planning and issue resolution

- AI-generated summaries of supply chain issues, including supplier-related impacts

- Future roadmap includes support for supplier communication tasks, such as escalation suggestions and message drafting

This level of intelligence enables teams to take action sooner, collaborate more effectively with vendors, and maintain a more resilient supply chain. As AI capabilities continue to evolve within Dynamics 365, supplier collaboration is becoming more predictive, connected, and responsive.

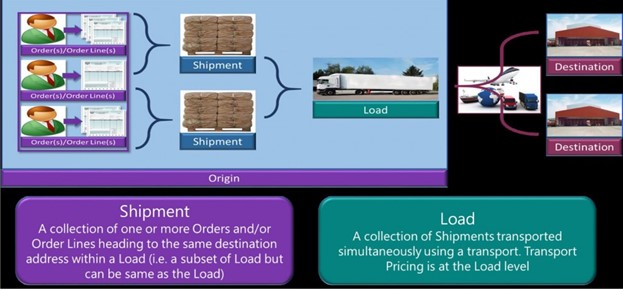

Unify Supply Chain Processes with an Integrated ERP System

Spreadsheets and disconnected tools might work in the short term, but over time they create silos, slow decision-making, and increase the risk of costly errors. As supply chains grow more complex, fragmented systems quickly become a barrier to efficiency.

Microsoft Dynamics 365 Supply Chain Management serves as a unified supply chain risk management platform. It connects procurement, inventory, production, logistics, and finance in a single cloud environment. When a purchase order is created, inventory levels update instantly, finance receives accurate cost data, and shipping information is tracked automatically. Every department works with the same real-time information, which improves coordination and eliminates gaps.

This level of integration eliminates manual handoffs, reduces duplicate data entry, and ensures every team operates with the same accurate information. Dynamics 365 also automates workflows and approval processes, improving efficiency and transparency across the entire supply chain.

According to Gartner, companies that adopt integrated supply chain platforms report faster and greater operational agility. For organizations in manufacturing, retail, or distribution, integration is no longer optional. A modern ERP platform is the backbone of scalable growth and gives businesses the agility, accuracy, and resilience needed to stay competitive.

Case in Action – MOC Products

MOC Products streamlined warehouse operations and improved forecasting accuracy by migrating to Dynamics 365. The result: fewer stockouts, reduced errors, and better on-time delivery.

Building Resilient Supply Chains with Dynamics 365 and Calsoft Systems

Supply chain disruptions are not going away. They are happening more often and across more complex global networks. Companies that want to stay competitive need to look beyond short-term fixes and invest in scalable, intelligent systems that support long-term resilience.

Microsoft Dynamics 365 Supply Chain Management, enhanced with AI capabilities like Copilot, gives organizations the ability to do just that. With predictive analytics, real-time visibility, automated planning, and built-in supplier risk management, the platform empowers businesses to make faster, smarter decisions across the entire supply chain.

But technology alone isn’t enough. You need the right strategy, the right setup, and the right support to make it work.

That is where Calsoft Systems steps in. As a trusted Microsoft Solutions Partner with decades of experience in ERP implementation and supply chain transformation, Calsoft helps businesses adopt Dynamics 365 with confidence. Whether you are upgrading from legacy systems or optimizing an existing environment, our team supports you every step of the way with planning, configuration, integration, training, and ongoing support. By implementing supply chain risk management solutions built on Dynamics 365, organizations can strengthen resilience and gain a competitive edge across their operations.

The future of supply chain management is proactive, data-driven, and AI-powered. With Dynamics 365 and Calsoft as your partner, you are not only prepared for what is ahead, you are positioned to lead.

Frequently Asked Questions (FAQ)

Supply chain risk management solutions in Microsoft Dynamics 365 involves using built-in ERP tools to identify, monitor, and reduce risks such as stockouts, supplier delays, compliance issues, and cybersecurity threats. Features like Inventory Visibility, Supply Chain Insights, and Planning Optimization provide real-time data to make proactive decisions.

AI enhances risk management by detecting anomalies, predicting potential disruptions, and recommending preventive actions. In Dynamics 365, AI tools such as Copilot and Supply Chain Insights help companies anticipate delivery delays, monitor supplier performance, and optimize logistics before issues escalate.

Dynamics 365 offers end-to-end visibility, integrated workflows, predictive analytics, and cloud-based security. Businesses gain more accurate demand forecasting, faster decision-making, reduced manual errors, and improved resilience against global disruptions.

Yes. Dynamics 365 integrates seamlessly with Microsoft Power BI and other ERP-friendly platforms. This enables organizations to build real-time dashboards, track KPIs such as supplier reliability and delivery performance, and make more informed supply chain decisions.

Power BI is not bundled by default with every Dynamics 365 license, but it integrates seamlessly with Dynamics 365 Supply Chain Management and other ERP/CRM modules. Organizations can connect Power BI to their ERP data to build interactive dashboards for real-time supply chain visibility. Some Dynamics 365 plans include limited Power BI features, while advanced analytics requires a separate Power BI Pro or Premium license.

Absolutely. While Dynamics 365 is built for enterprise scalability, it is also flexible for small and mid-sized businesses. Cloud deployment reduces IT overhead, improves security, and allows growing companies to adopt enterprise-grade supply chain tools without large infrastructure costs.